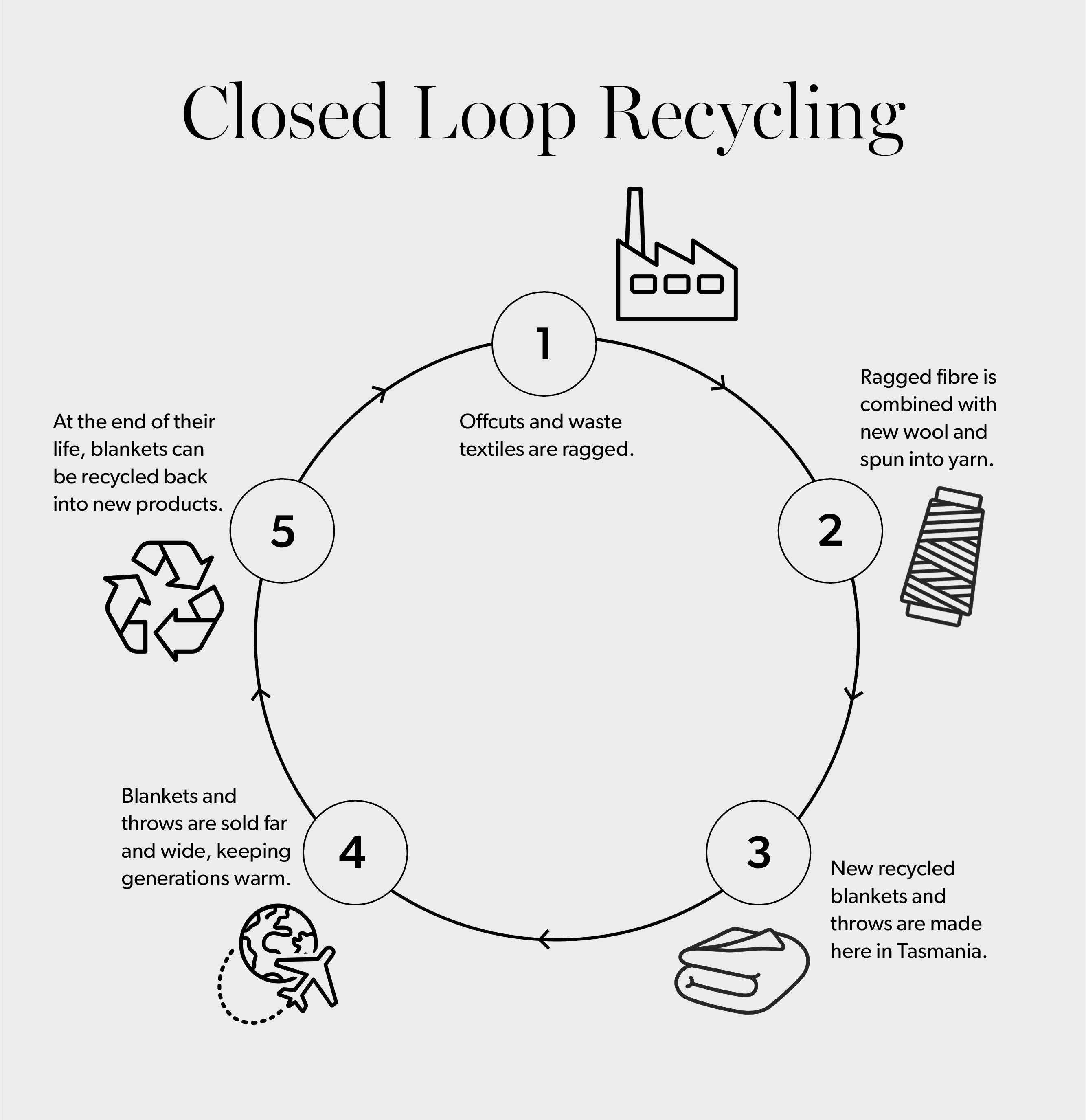

How is Wool Recycled at Waverley Mills

We’ve perfected a wool recycling process that honours the craftsmanship of the past while embracing sustainable innovation for the future.

Step One

Ragging & Blending

We are deeply committed to reducing waste and making the most of every fibre. That’s why we collect wool off-cuts and surplus material from our factory floor and collaborating with our partners to collect old or unused textiles, ensuring that nothing goes to waste. These fibres are sent through our ragger—a specialist machine that carefully breaks down woven and spun fabric, transforming it back into a raw, usable state, ready for a new life.

Once processed, this recycled fibre is blended with high-quality new wool and fed into our carding line. Here, the fibres are meticulously aligned and arranged into a delicate web, ensuring even distribution before they are prepared for spinning. This blending process is key to maintaining the strength, softness, and integrity of our final yarn, seamlessly integrating recycled material with fresh wool fibres.

Step Two

Carding & Spinning

At the end of the carding line, the fibres are gently twisted together to create a semi-spun yarn, which is then further refined on our spinning frame. This step enhances the strength and consistency of the yarn, ensuring it meets our exacting standards for weaving. The result is a beautifully balanced woollen yarn—composed of 20% recycled wool fibre and 80% new wool—that retains the warmth, durability, and luxurious softness Waverley Mills is known for.

Step Three

Dyeing & Weaving

Once spun, the yarn is dyed where needed, before being woven into our signature recycled range. Every piece then undergoes a meticulous finishing process, including inspection, milling, raising, and final touches that enhance the texture and longevity of the fabric. The result is a stunning, high-quality recycled wool throw or blanket, ready to bring warmth, comfort, and sustainability into your home.

Why Choose Recycled Wool?

-

Reduces textile waste through reuse

By reclaiming offcuts and discarded fabrics, recycled wool keeps valuable fibres in circulation instead of going to landfill.

-

Delivers environmental benefits by lowering energy and water consumption

Recycling wool uses fewer resources than producing new fibres, helping us conserve what matters most.

-

Offers warmth, durability, and comfort

Recycled wool fabric is soft, breathable, and strong — designed to be lived with and loved for years.

-

Helps build a more sustainable future

Every Waverley Mills piece shows how reuse can create lasting beauty, proving that waste can become opportunity.

Shop Recycled Wool Bestsellers

Crafted in Tasmania for 150 years

Frequently asked questions

What is recycled wool?

Recycled wool is created by reclaiming offcuts and repurposing discarded fabrics giving fibres a second life. At Waverley Mills, this wool recycling process has been part of our story for decades. The result is a recycled wool fabric that offers the same softness, warmth, and durability our products are known for, only with less waste and a lighter footprint.

What are the benefits of recycled wool?

The benefits of recycled wool go beyond softness and warmth. By reusing fibres, we reduce textile waste, conserve water and energy, and lower the environmental footprint of every product. Recycled wool fabric is durable, breathable, and sustainable, making it a choice that’s kinder to the planet while still delivering comfort and quality.

How does recycled wool compare to virgin wool?

Virgin wool is made from freshly shorn sheep fleece, while recycled wool reuses fibres that have already been spun once before. Both create warm, strong, and natural fabrics. The key difference is environmental impact: recycled wool reduces waste and resource use, offering all the qualities of virgin wool with added sustainability benefits.